How To Map Machine Data and Standardize It for Industrial Connectivity

This article explores the process of mapping machine data, its importance in achieving standardization, and how it enhances integration, scalability, and interoperability across industrial systems.

Table of Contents:

- Why data mapping matters in industrial connectivity

- What is data mapping in industrial environments?

- How to standardize machine data for seamless industrial connectivity

- Key steps in machine data mapping

- Challenges in machine data mapping and how to overcome them

- Our solution for scalable and maintainable data mapping

- Conclusion and how to get started

1. Why Data Mapping Matters in Industrial Connectivity

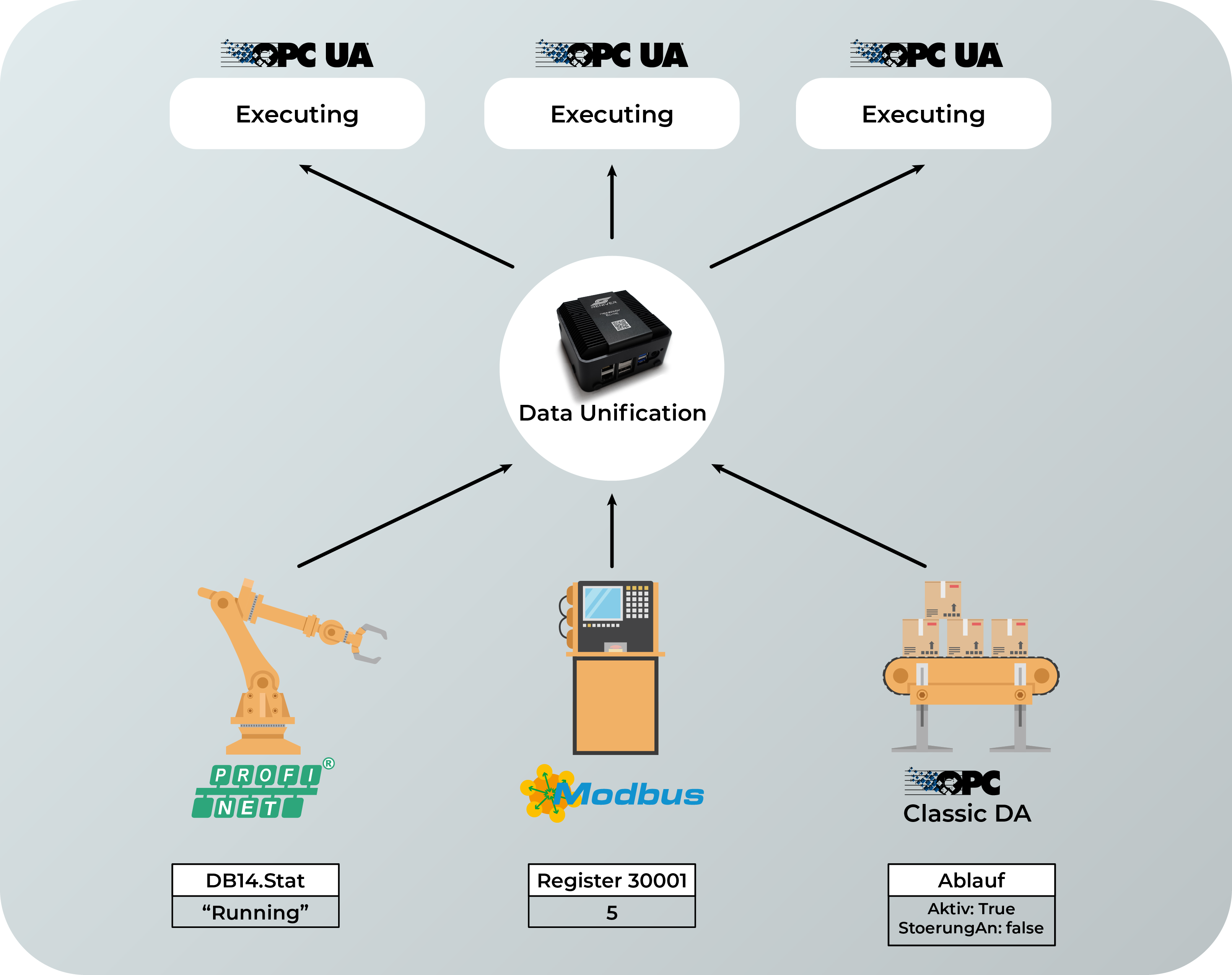

Before industrial systems can communicate effectively, they need to understand each other by speaking the same language. That starts with how machine data is structured. Data mapping plays a foundational role in bridging this gap, ensuring that information generated on the shop floor can be used meaningfully across systems, from local controllers to enterprise applications.

Why structured data is essential for machine connectivity and automation.

Industrial machines generate vast amounts of data, but this data is often fragmented and inconsistent. Different machines, sensors, and controllers use unique formats, naming conventions, and communication protocols, making direct integration difficult.

Data mapping standardizes this raw information, ensuring all devices, systems, and applications interpret it correctly. This allows seamless data exchange, improving interoperability between machines and higher-level systems like SCADA, MES, and cloud platforms. A structured approach also eliminates the need for extensive custom integration work, reducing complexity and implementation time.

How standardized data benefits MES, SCADA, cloud, and other systems.

Once machine data is structured, it becomes significantly more useful across various platforms:

- MES (Manufacturing Execution Systems): Uses standardized data for accurate production tracking and process optimization.

- SCADA (Supervisory Control and Data Acquisition): Requires real-time, well-structured machine data for monitoring and control.

- Cloud-Based analytics: Processes machine data for predictive maintenance, performance optimization, and long-term trend analysis.

By ensuring a unified data structure, data mapping prevents miscommunication between Operational Technology (OT) and Information Technology (IT) systems. Without a consistent format, machine data may be misinterpreted or even lost in translation when moving between factory-floor devices and enterprise-level applications.

Well-executed data mapping enables industrial environments to move beyond isolated machine data, allowing for real-time insights, system-wide automation, and data-driven decision-making.

2. What Is Data Mapping in Industrial Environments?

The term data mapping can mean different things depending on the context, such as database integration or business intelligence workflows. In industrial environments, however, it takes on a very specific role: making raw, often unstructured machine data usable across systems. Below, we outline what data mapping means in industrial settings and how it enables reliable system-to-system communication.

Definition of data mapping in industrial automation.

Data mapping in industrial automation is the process of structuring and converting raw machine data into a standardized format that can be understood across different systems. It ensures that data from various machines, sensors, and controllers is accurately interpreted by industrial systems like MES or cloud-based analytics platforms.

How data mapping translates raw machine signals into structured, usable information.

Industrial machines generate data in different formats, using proprietary naming conventions and communication protocols. Without mapping, this data is often unreadable or inconsistent when transferred between systems.

Data mapping solves this by:

- Assigning tags and variables: Machine-generated data points (e.g., temperature, speed, pressure) are labeled with consistent tags to enable easy identification across systems.

- Defining a hierarchical structure: Data is organized logically, grouping related values under machine components or processes for better readability.

- Standardizing data formats: Units, timestamps, and data types are converted to a common structure, ensuring compatibility between different industrial applications.

- Using industrial standards for compatibility: To enable seamless data exchange, industrial protocols like OPC UA, MQTT, PROFINET, and Modbus provide predefined models and communication rules that help structure machine data in a universally accepted format.

3. How To Standardize Machine Data for Seamless Industrial Connectivity

Standardization ensures that machine data is structured in a consistent format, making it compatible across different systems. Without a unified structure, integrating data from multiple machines, vendors, or industrial protocols becomes complex and inefficient. Several industry standards help achieve this by defining how data is organized, labeled, and shared.

Using OPC UA for data standardization

OPC UA provides a structured address space model, organizing data into a hierarchical format that machines and software can interpret consistently. It also includes Companion Specifications, which define predefined models tailored to specific industries, such as robotics, manufacturing, and energy.

By using information models, OPC UA ensures that all devices and systems following the standard represent machine data in a uniform way. This improves interoperability and reduces the need for custom data mappings between different industrial components.

👉 Want to know more about OPC UA and its importance in industrial data standardization? Read our OPC UA article here

Alternative industrial standards

Other widely used industrial standards also structure data but serve different purposes:

-

MQTT (Message Queuing Telemetry Transport): Uses a publish/subscribe model for lightweight, real-time data exchange, commonly used in IIoT applications.

-

PROFINET: A real-time Ethernet standard designed for high-speed industrial automation and machine-to-machine communication.

-

Modbus: One of the oldest industrial protocols, used for simple data exchange between industrial devices.

Each of these protocols has its own method for structuring and transmitting data, making it important to choose the right one based on system needs.

Aligning data structures across different systems

In industrial environments, machine data needs to be shared between SCADA, MES, and enterprise IT systems, each requiring data in a specific format. Standardization ensures that data flows between these systems without the need for manual conversion or data loss.

To unify data across different platforms:

-

Ensure a consistent data format across machines and software applications.

-

Use middleware or protocol converters to translate between different industrial communication standards.

-

Implement structured data models to maintain uniformity across field devices and enterprise systems.

These standardization methods provide the foundation for effective machine-to-machine communication, process automation, and data-driven decision-making.

4. Key Steps in Machine Data Mapping

Once machine data is standardized, it must be properly mapped to ensure compatibility across different systems. Data mapping assigns meaning to machine-generated data, defining how it should be structured, labeled, and processed.

Identifying data sources

Before mapping can begin, it's essential to identify where data is coming from:

-

PLCs (Programmable Logic Controllers)

-

Sensors (temperature, pressure, vibration, etc.)

-

CNC controllers and industrial machines

Each device may output data in a different format, requiring standardization and mapping before integration into higher-level systems.

Defining a standard data model

To achieve interoperability, machine data needs to follow a structured model. This involves:

-

Choosing the right standard for your system:

-

OPC UA: Best for structured, hierarchical data exchange with built-in security and scalability.

-

MQTT: Ideal for lightweight, publish/subscribe messaging in IIoT applications.

-

PROFINET & Modbus: Common for real-time field communication and legacy systems.

-

-

Mapping machine data to these standards

-

Ensuring that machine-generated variables align with the selected standard's data structure.

-

Converting units, timestamps, and variable names to match the expected format.

-

Choosing the right standard depends on real-time performance needs, network architecture, and system compatibility.

Handling different data types and units

Machines from different manufacturers may use varying units, formats, or naming conventions for similar data points. Proper mapping involves:

-

Normalizing units (e.g., converting pressure from PSI to bar where needed).

-

Ensuring consistent data types (e.g., integer vs. floating point values).

-

Timestamp synchronization for accurate event tracking.

This step ensures that all connected systems interpret data in the same way, preventing calculation errors and miscommunication.

Ensuring data quality

Raw machine data often contains missing values, outliers, or inconsistencies. Effective data mapping should include validation steps to:

-

Filter out invalid readings (e.g., sensor errors).

-

Handle missing data by interpolating or flagging gaps.

-

Apply threshold-based alerts for detecting anomalies.

By maintaining high-quality data, mapped machine values remain reliable for monitoring, automation, and analytics.

5. Challenges in Machine Data Mapping and How To Overcome Them

Data mapping in industrial environments comes with challenges, especially when dealing with legacy equipment, proprietary formats, and large-scale deployments. Addressing these issues ensures a more efficient and scalable data integration process.

Dealing with legacy machines

Many industrial systems still rely on older PLCs, controllers, and sensors that lack modern communication standards. These machines often use serial connections or proprietary fieldbus networks, making integration difficult.

Solutions:

- Protocol converters and gateways: Translate legacy data formats into modern standards like OPC UA or MQTT.

- Edge devices: Preprocess and map data before sending it to higher-level systems.

Extracting data from these machines requires protocol translation and structured mapping, but once integrated, it enables seamless automation.

👉 Working with legacy machines that weren't built for connectivity? Learn how to integrate them securely and efficiently in our article on legacy machine integration.

Handling proprietary or encrypted data formats

Some machine manufacturers use closed data structures or encryption, preventing direct data access.

Solutions:

-

Middleware & data translators: Convert proprietary data into open formats.

-

Reverse engineering: Analyzing machine outputs to decode undocumented data structures.

-

OEM collaboration: Working with vendors to access machine data securely.

-

Using external sensors: Installing independent sensors (e.g., vibration, temperature, energy meters) to capture critical machine data without relying on manufacturer-provided access.

Unlocking proprietary data allows full control over machine insights and analytics while ensuring vendor independence.

Ensuring scalability

As facilities grow, managing multiple machines and large datasets becomes complex. A scalable data mapping platform like Reniway helps simplify this process by:

-

Low-Code UI: Quickly adapts to new machines with minimal setup.

-

Reusable mapping templates: Standardized configurations reduce effort in large deployments.

-

Centralized configuration: Simplifies maintenance across multiple sites.

A structured mapping strategy prevents complexity from slowing down industrial expansion.

6. Our Solution for Scalable and Maintainable Data Mapping

Effective data mapping requires the right tools to streamline the process and ensure consistency across machines and systems. Industrial environments often deal with complex data structures, so low-code solutions, reusable templates, and automation tools can significantly reduce integration time and effort.

Reniway's flow-based UI for easy data mapping

Traditional data mapping often requires extensive scripting and manual configuration, making integration time-consuming. Reniway simplifies this process with a flow-based UI that allows engineers to map machine data visually, using an intuitive drag-and-drop interface.

-

Low-Code data transformation: Users can define how data points are structured, renamed, or converted without writing custom scripts.

-

Minimal programming effort: Unlike traditional middleware solutions, Reniway reduces the need for deep coding expertise, making data mapping accessible to both automation engineers and IT teams.

-

Real-Time adjustments: Mappings can be modified on the fly to accommodate changes in machine configurations.

By eliminating the complexity of manual data transformation, Reniway accelerates the deployment of standardized machine data across industrial networks.

👉 Want to see Reniway in action? Check out our video tutorials on the docs page for a hands-on demonstration of how to set up and apply data mappings.

Reusable templates for large-scale projects

In facilities with multiple machines or production lines, manually configuring each data mapping setup is inefficient. Reniway provides a template-based approach, allowing users to:

-

Save predefined data mappings for specific machine types or production processes.

-

Apply templates to new machines without repeating the setup process.

-

Standardize mappings across multiple sites, ensuring consistency in large-scale deployments.

This feature reduces engineering workload, enhances scalability, and prevents configuration errors when integrating new equipment.

Other industry tools and middleware

While Reniway offers a streamlined, low-code approach, other tools are available for industrial data mapping, depending on system requirements:

-

OPC UA modelers -- Used to design and define structured data models within an OPC UA environment.

-

Custom middleware (e.g., Node-RED, Python Scripting) -- Useful for advanced data transformation needs where automation logic is required.

-

Enterprise integration platforms (e.g., MQTT Brokers, SCADA data gateways) -- Convert and transmit data between field devices and cloud analytics platforms.

Selecting the right tool depends on the complexity of the data mapping task, system compatibility, and the level of automation required.

7. Conclusion and How To Get Started

To integrate machines effectively into modern industrial systems, machine data must be structured and standardized. Without proper data mapping, differences in formats, protocols, and system architectures create inefficiencies and integration challenges. By using industrial standards like OPC UA, MQTT, and PROFINET, companies ensure seamless communication between SCADA, MES, and cloud platforms.

With the right tools and strategies, businesses can overcome challenges such as legacy machine connectivity, proprietary data formats, and scalability. Standardized data mapping not only simplifies system integration but also enables real-time monitoring, predictive maintenance, and data-driven decision-making in industrial automation.

Next steps for companies looking to improve data integration

-

Assess your current infrastructure and identify data sources.

-

Choose the right standard (OPC UA, MQTT, PROFINET, Modbus) based on system needs.

-

Implement a scalable mapping solution to reduce integration complexity.

Don't know how to proceed or need expert guidance?

Every industrial environment has unique challenges when it comes to data integration. Whether you need tailored expert guidance for complex setups or a scalable solution for standardizing machine data, we can help.

With Reniway's low-code, flow-based UI and reusable templates, you can efficiently map and standardize machine data across different systems. For more complex environments, our experts provide customized integration strategies to ensure seamless communication between Industrial software & IT, cloud platforms, and machines.

👉 Get in touch to discuss your specific needs or check out our video tutorials to see how Reniway simplifies data mapping in action.