What Is OPC UA? Understanding the Standard for Industrial Connectivity

A comprehensive overview of OPC UA, its benefits, and its importance in industrial automation.

Source: OPC Foundation

Source: OPC Foundation

Table of Contents:

- Introduction

- What is OPC UA?

- The role of OPC UA in machine connectivity and industry 4.0

- Challenges in implementing OPC UA

- How to get started with OPC UA

1. Introduction

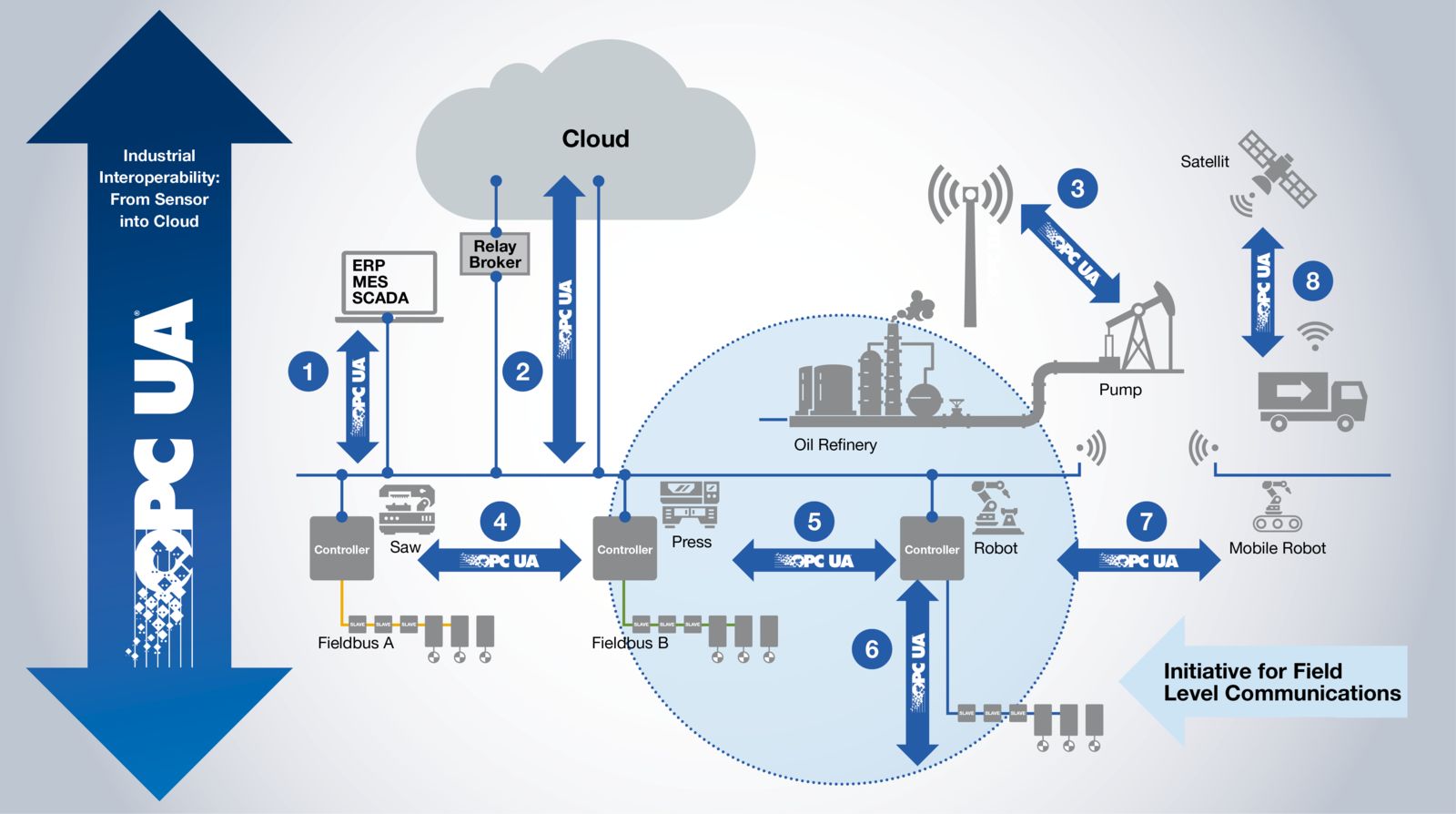

In industrial automation, seamless communication between machines, devices, and software systems is critical to achieving efficiency and scalability. However, the diverse array of equipment, each with its own protocols and data structures, often creates significant challenges in connectivity. This is where OPC UA (Open Platform Communications Unified Architecture) plays a transformative role.

As a cross-platform, open standard for data exchange, OPC UA enables machines and systems to communicate seamlessly, regardless of their manufacturer, operating system, or location. By providing a standardized approach to sharing information, it ensures interoperability across the industrial ecosystem which is an essential requirement for Industry 4.0 and the development of smart factories.

This article explores what OPC UA is, its role in industrial machine connectivity, and why it is a cornerstone technology for businesses striving to align with Industry 4.0 principles. From its key features and benefits to its implementation challenges, we'll provide a comprehensive understanding of this critical standard and its application in modern industrial environments.

2. What Is OPC UA?

Definition and origins

OPC UA (Open Platform Communications Unified Architecture) is an industrial communication protocol designed to enable seamless, secure, and standardized data exchange between machines, devices, and systems. Building on its predecessor, OPC Classic, which primarily facilitated data exchange in Windows environments, OPC UA was introduced in 2006 by the OPC Foundation to address the limitations of platform dependency and security in industrial communication.

Unlike OPC Classic, which relied on COM/DCOM technologies, OPC UA is platform-independent, allowing it to run on a variety of operating systems, including Linux, macOS, and embedded systems. Its extensible architecture enables interoperability across diverse equipment and systems, making it foundational to modern Industry 4.0 initiatives.

Key features of OPC UA

-

Platform Independence: OPC UA is designed to work across multiple platforms, from embedded systems to enterprise-level servers. This is achieved through its use of binary encoding and standard internet protocols like TCP/IP and HTTPS. By avoiding reliance on proprietary software or hardware, OPC UA enables manufacturers to integrate devices and systems from different vendors seamlessly.

-

Scalability: OPC UA supports deployment across a wide range of applications, from lightweight devices like sensors to high-performance industrial servers. Its ability to scale ensures it can handle everything from a single device's data to large-scale operations involving hundreds of interconnected devices.

-

Security: Security is built into the core of OPC UA, addressing critical concerns in industrial environments. Key features include:

-

Encryption of data during transmission using standards like TLS.

-

Authentication via X.509 certificates, ensuring only authorized clients and servers can communicate.

-

Data integrity checks to prevent tampering.

-

-

Pub/Sub Model: OPC UA supports a Publisher/Subscriber (Pub/Sub) communication model in addition to its traditional client-server architecture. This makes it ideal for use cases requiring high-performance, real-time data exchange, such as predictive maintenance and machine monitoring.

-

Publisher/Subscriber model: Publishers send data to multiple subscribers over common network transport protocols like MQTT or UDP, enabling efficient one-to-many or many-to-many communication.

-

Client/Server model: The traditional model where clients explicitly request data from servers, ensuring precise control over data exchange.

-

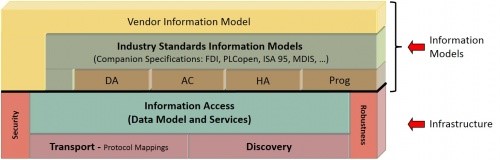

OPC UA Specifications

The OPC UA standard is defined by a comprehensive set of specifications maintained by the OPC Foundation. These include:

-

Address space model: Defines how data is structured and accessed within the OPC UA environment. The model uses nodes to represent data points and their relationships, enabling a rich semantic understanding of the data.

-

Services: A suite of services supports data access, event notifications, and historical data retrieval.

-

Transport protocols: Provides flexibility with options like binary (for high performance) and HTTPS (for web-based applications).

-

Information modeling: Extends OPC UA to specific industries by defining domain-specific data models, such as those for manufacturing, energy, or healthcare.

OPC UA Industry-specific standards

OPC UA's flexibility is further enhanced by its ability to define industry-specific standards through Companion Specifications. These specifications are developed in collaboration with various industry groups to extend OPC UA's functionality, tailoring it to the needs of specific sectors. By adopting these standards, industries can ensure interoperability and uniformity across their unique equipment and applications.

Source: OPC Foundation

Here are some key Industry-Specific Standards

-

OPC UA for Machinery: Designed for machinery manufacturers, this specification enables seamless integration and monitoring of machines from different vendors, supporting advanced analytics and diagnostics.

-

OPC UA for Robotics: Provides standardized data models for robot control and monitoring, enabling easier integration of robotic systems into broader industrial workflows.

-

OPC UA for Energy: Tailored for energy management and smart grids, this specification supports data exchange between energy devices and systems, ensuring efficient operation and monitoring.

-

OPC UA for Pharma and Biotech: Facilitates data traceability and regulatory compliance by creating standardized models for monitoring and controlling pharmaceutical processes.

Explore OPC UA companion standards: If you want to explore the complete list of OPC UA Companion Standards and find the ones most relevant to your industry, visit the official OPC UA standards database: https://opcfoundation.org/developer-tools/documents/

Benefits of industry-specific standards

-

Enhanced interoperability: Devices and systems within the same industry can exchange data seamlessly.

-

Reduced integration time: Predefined models eliminate the need for custom mappings.

-

Compliance Support: Ensures adherence to industry regulations and best practices.

Comparison with other industrial protocols

-

OPC Classic:

-

Limited to Windows environments due to its reliance on COM/DCOM.

-

Lacks built-in security features.

-

Cannot handle platform-independent communication.

-

-

Modbus:

-

Primarily focused on field-level communication.

-

Simpler but lacks the semantic capabilities and robust security of OPC UA.

-

-

PROFINET:

-

Focused on real-time Ethernet communication for automation systems.

-

Strong in specific applications but less flexible for cross-industry use compared to OPC UA.

-

-

MQTT:

- A lightweight protocol ideal for IoT applications but lacks the rich data model and comprehensive specifications offered by OPC UA.

3. The Role of OPC UA in Machine Connectivity and Industry 4.0

OPC UA plays a crucial role in modern industrial systems by enabling seamless communication between machines, devices, and software systems. Its ability to provide structured, standardized data exchange is essential for building interconnected environments and advancing Industry 4.0 initiatives like smart factories and predictive analytics.

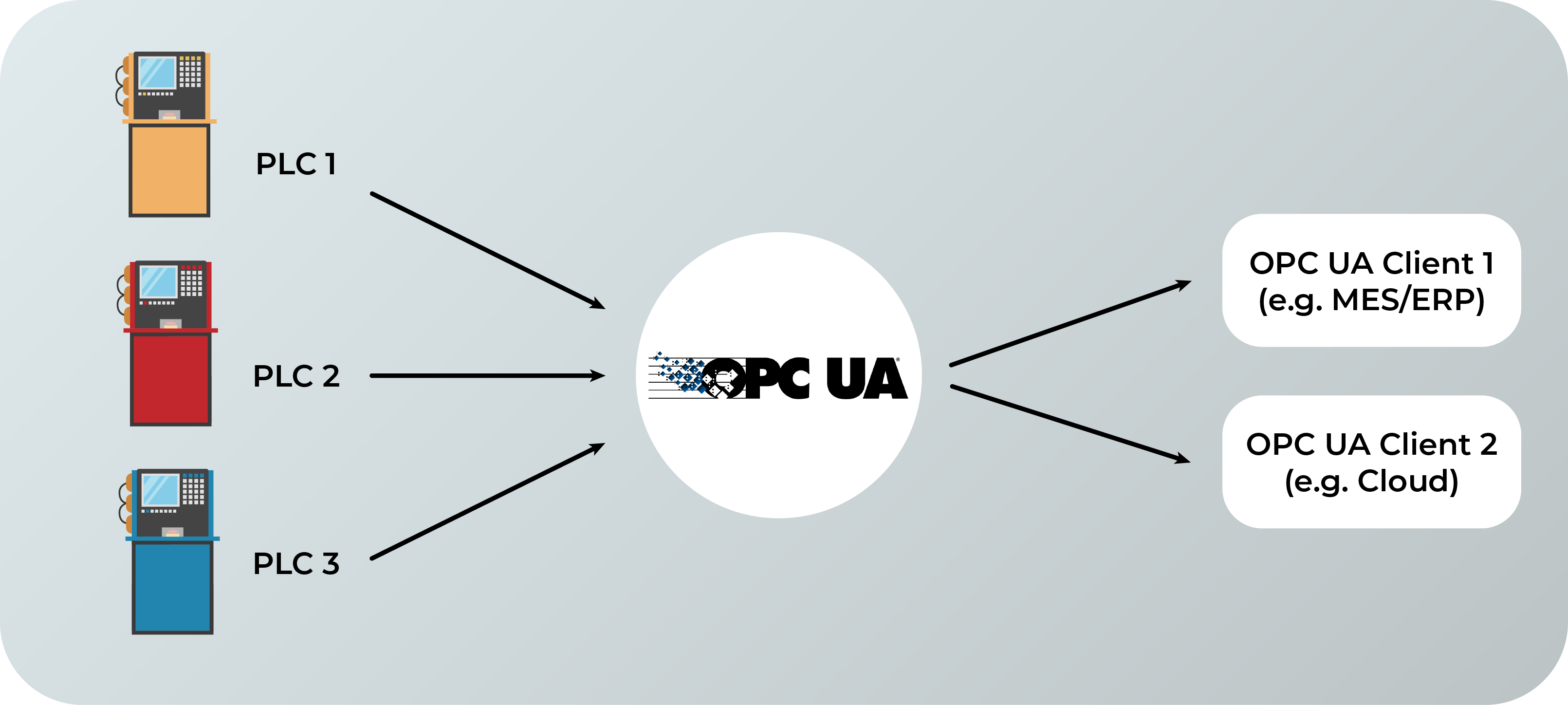

How OPC UA connects machines

OPC UA excels in creating a common communication framework that integrates disparate systems, such as PLCs, SCADA systems, MES, and cloud platforms. Its address space model structures data in a way that both humans and machines can understand, ensuring that all connected systems interpret and exchange information consistently.

For example:

-

Production monitoring: A machine's operational data (e.g., speed or temperature) can be sent to a monitoring dashboard in real time.

-

Error handling: An OPC UA server can notify a maintenance system of an issue, triggering alerts for rapid resolution.

Real-Time data for industrial processes

One of OPC UA's standout capabilities is enabling real-time data exchange, critical for applications like process control, predictive maintenance, and energy optimization. Through the Pub/Sub communication model, OPC UA efficiently handles real-time updates by broadcasting data to multiple subscribers, ensuring fast and scalable communication.

Driving industry 4.0 initiatives

Industry 4.0 emphasizes automation, interconnectivity, and data-driven decision-making. OPC UA is uniquely positioned to support these goals by:

-

Facilitating interoperability: OPC UA allows machines, regardless of vendor or age, to share data using standardized models. This eliminates the silos traditionally present in industrial environments.

-

Enabling digital twins: Digital twins rely on real-time data to mirror physical machines virtually. OPC UA's ability to provide structured, accurate, and up-to-date information makes it an essential component of these virtual models.

-

Supporting predictive analytics: By integrating OPC UA with advanced analytics platforms, manufacturers can predict machine failures or quality issues before they occur, minimizing downtime and costs.

-

Streamlining supply chain operations: With data from OPC UA-enabled devices, manufacturers can share operational insights with suppliers and logistics providers, optimizing supply chain performance.

Integration with emerging technologies

OPC UA is increasingly used alongside technologies such as artificial intelligence (AI) and edge computing:

-

AI systems can leverage structured OPC UA data for anomaly detection and process optimization.

-

Edge devices use OPC UA to collect and preprocess data from machines before transmitting insights to the cloud.

4. Challenges in Implementing OPC UA

Despite its significant advantages, implementing OPC UA in industrial environments comes with several challenges. These issues are often tied to the complexity of existing systems, the expertise required, and the scale of deployment. Addressing these challenges effectively is key to realizing the full benefits of OPC UA.

Compatibility with legacy systems

One of the biggest hurdles in adopting OPC UA is integrating it with legacy machines and equipment that were not designed with modern communication protocols in mind. These systems often:

-

Lack native OPC UA support.

-

Use proprietary or outdated communication protocols (e.g., Modbus or custom serial interfaces).

-

Require additional hardware, such as protocol converters or edge devices, to bridge the gap between legacy systems and OPC UA.

👉 Working with legacy machines that weren't built for connectivity? Learn how to integrate them securely and efficiently in our article on legacy machine integration.

Required expertise in data modeling and configuration

Implementing OPC UA involves more than just hardware and software installation. It requires:

-

Data Modeling Skills: Creating and managing the OPC UA address space model, including defining nodes, variables, and relationships, can be a complex task that demands an understanding of the machine's operational data.

-

Configuration Expertise: Configuring servers and clients to handle specific use cases, like historical data access or event notifications, can vary significantly between implementations.

-

Information Model Integration: Mapping industry-specific models (e.g., Companion Specifications) to your system often requires customization and domain knowledge.

Organizations without in-house expertise may face steep learning curves, making external training or consultation essential for successful deployment.

Managing large-scale deployments

As the scale of deployment grows, so do the challenges:

-

Network Performance: Real-time data exchange can strain networks, especially in environments with high-frequency data streams.

-

System Complexity: Managing hundreds of OPC UA nodes and ensuring their proper configuration and maintenance requires robust system monitoring and management tools.

-

Security Overheads: Large-scale implementations involve managing certificates and authentication for numerous devices, which can become a logistical challenge.

Addressing these challenges

While these challenges can be significant, solutions exist:

-

For legacy systems: Use protocol converters or replace outdated components with OPC UA-compatible ones during upgrades.

-

For expertise needs: Invest in training or collaborate with experts familiar with OPC UA deployment.

-

For large-scale deployments: Utilize tools for automated configuration and certificate management, and design a network architecture optimized for OPC UA communication.

5. How To Get Started With OPC UA

Implementing OPC UA in your industrial environment requires careful planning, the right tools, and expertise. Whether you're integrating new systems or retrofitting existing ones, following a structured approach will ensure a smoother transition and long-term success.

Steps for integrating OPC UA

-

Define your use cases and objectives

-

Decide on key applications, such as real-time monitoring, historical data access, or predictive maintenance.

-

Map out the data points you need to capture and how they align with operational goals.

-

-

Assess your existing infrastructure

-

Identify machines and devices that need to be connected.

-

Determine if they natively support OPC UA or require protocol converters or additional hardware (e.g., edge devices).

-

Evaluate your network's capacity to handle real-time data exchange.

-

-

Develop or adopt an information model

-

Use industry-specific OPC UA Companion Specifications to create standardized data structures.

-

Customize the address space model to represent your devices and processes accurately.

-

-

Set up OPC UA servers and clients

-

Install and configure OPC UA servers on compatible devices or intermediary hardware.

-

Configure clients to connect to these servers and request, monitor, or log data.

-

-

Implement security measures

-

Use X.509 certificates for device authentication.

-

Ensure secure data transmission with encryption protocols like TLS.

-

-

Test and validate the setup

-

Perform integration tests to ensure data flows correctly between devices and systems.

-

Monitor performance under normal and high-load conditions.

-

Tools and resources for implementation

-

OPC UA Development kits Development SDKs (e.g., Unified Automation, Prosys OPC) provide libraries and tools to create custom OPC UA servers or clients tailored to your system.

-

Network monitoring tools Use tools like Wireshark to analyze data packets and troubleshoot communication issues.

-

OPC UA Configuration software Tools like UA Expert allow you to browse servers, monitor variables, and test connections during the setup phase.

-

Standards and documentation Refer to official resources, such as the OPC Foundation website, for Companion Specifications and best practices.

Partnering with experts for a seamless transition

For organizations lacking in-house expertise, partnering with OPC UA specialists can expedite the implementation process:

-

Consultants: Help with initial infrastructure assessment and planning.

-

Vendors: Provide pre-configured hardware and software solutions for faster deployment.

-

Training providers: Offer courses on OPC UA architecture, security, and configuration tailored to your team's needs.

Since 2014, Reniver has been helping industrial companies implement OPC UA across a wide range of machines, systems, and environments. Whether you're working with new equipment or integrating legacy infrastructure, our team can guide you through a secure, standardized rollout which is aligned with your existing architecture and future goals.

Contact us to start a conversation.